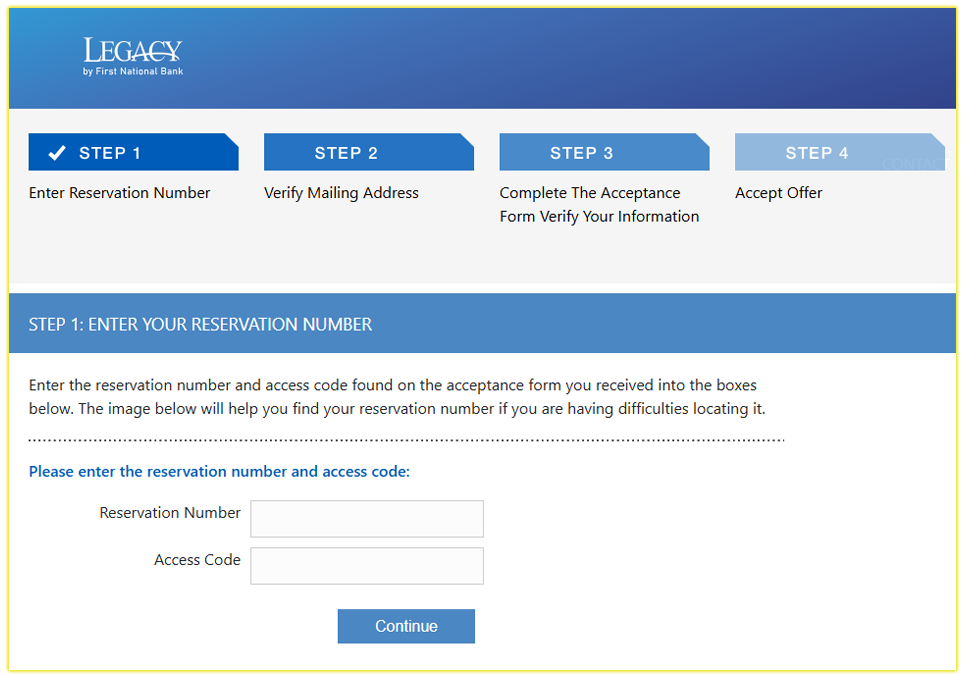

When I first started digging into the concept of return on working capital supply chain, I’ll admit it felt like trying to unravel a puzzle. I mean, supply chain management already has so many moving parts, inventory, logistics, supplier payments, and then you throw in financial metrics? It can seem like a lot. But stick with me, because I’m going to break it down for you in a way that’s clear, practical, and dare I say, even a little fun. Whether you’re running a small business or managing a large operation, understanding this metric can help you make smarter decisions and keep your cash flow healthy.

In this article, I’ll walk you through what return on working capital in the supply chain means, why it matters, and how you can calculate it step-by-step. I’ll also share some real-world examples, tips to improve it, and answer common questions. By the end, you’ll have a solid grasp of how to use this metric to optimize your supply chain and boost your business’s efficiency.

How Do You Calculate Return on Working Capital Supply Chain?

Let me start by explaining what I mean by return on working capital supply chain. In simple terms, it’s a way to measure how efficiently your business is using its working capital, think cash, inventory, and accounts receivable, to generate profits through your supply chain operations. Working capital is the lifeblood of your business; it’s the money you use to keep things running day-to-day. This metric tells you how much return (or profit) you’re getting for every dollar tied up in your supply chain.

To calculate it, you need two main pieces of information: your supply chain’s operating income and your working capital. Here’s the formula in its simplest form:

Return on Working Capital Supply Chain = (Operating Income from Supply Chain / Working Capital) × 100

This gives you a percentage that shows how much profit your supply chain generates relative to the working capital invested in it. Let me break it down further so you can see how it works in practice.

Step 1: Calculate Operating Income from Supply Chain

First, you need to figure out the operating income tied to your supply chain. This is the profit your business makes from its core supply chain activities before subtracting things like taxes or interest. To get this number, you’ll typically look at:

- Revenue from sales: The money you make from selling your products.

- Cost of goods sold (COGS): This includes the direct costs of producing or acquiring the goods you sell, like raw materials or supplier payments.

- Supply chain operating expenses: Think warehousing, transportation, and labor costs directly tied to your supply chain.

Here’s an example to make it clear. Imagine you run a small business selling handmade candles. Your annual sales are $100,000. The cost of wax, wicks, and packaging (your COGS) is $40,000, and your supply chain expenses (like shipping and storage) total $20,000. Your operating income would be:

$100,000 (revenue) – $40,000 (COGS) – $20,000 (supply chain expenses) = $40,000

That $40,000 is your operating income from supply chain activities. Keep this number handy—you’ll need it later.

Step 2: Determine Your Working Capital

Next, you need to calculate your working capital, which is the money tied up in your day-to-day operations. The formula for working capital is:

Working Capital = Current Assets – Current Liabilities

Current assets include things like cash, inventory, and accounts receivable (money customers owe you). Current liabilities are what you owe in the short term, like accounts payable (money you owe suppliers) or short-term loans.

Let’s go back to our candle business. Say you have:

- Cash: $10,000

- Inventory: $15,000 worth of candles and materials

- Accounts Receivable: $5,000 from customers who haven’t paid yet

That’s $30,000 in current assets. Now, let’s say you owe $8,000 to suppliers and have a $2,000 short-term loan. Your current liabilities total $10,000. Your working capital is:

$30,000 (current assets) – $10,000 (current liabilities) = $20,000

This means you have $20,000 tied up in your supply chain operations.

Step 3: Plug It Into the Formula

Now that you have both numbers, calculating the return on working capital supply chain is straightforward. Using our example:

Return on Working Capital Supply Chain = ($40,000 / $20,000) × 100 = 200%

A 200% return means that for every dollar you have tied up in working capital, you’re generating $2 in profit from your supply chain. Pretty impressive, right? But what does this number actually tell you? Let’s explore that next.

Why Does Return on Working Capital Supply Chain Matter?

I can’t stress enough how important it is to keep an eye on this metric. When I first started looking at my own business’s numbers, I realized that understanding return on working capital helped me spot inefficiencies I didn’t even know existed. For you, it’s like a health check-up for your supply chain. A high return means your supply chain is lean and efficient, turning your invested capital into profits quickly. A low return might signal that you’re tying up too much money in inventory or not managing your supplier payments well.

This metric also helps you compare your performance to competitors or industry benchmarks. For example, if your industry’s average return on working capital is 150%, and you’re sitting at 50%, it’s a red flag that something’s off. Maybe your inventory is sitting on shelves too long, or your logistics costs are eating into your profits. Knowing this gives you a starting point to make changes.

Real-World Example: A Retail Store

To make this more relatable, let’s look at another example. Imagine you own a retail clothing store. Your supply chain involves buying clothes from suppliers, storing them in a warehouse, and shipping them to your store. Here’s how you might calculate your return on working capital supply chain:

- Revenue: $500,000 from clothing sales.

- COGS: $200,000 for purchasing the clothes.

- Supply chain expenses: $100,000 for warehousing, shipping, and labor.

- Operating Income: $500,000 – $200,000 – $100,000 = $200,000.

- Current Assets: $50,000 (cash) + $100,000 (inventory) + $20,000 (accounts receivable) = $170,000.

- Current Liabilities: $50,000 (accounts payable) + $10,000 (short-term loans) = $60,000.

- Working Capital: $170,000 – $60,000 = $110,000.

- Return on Working Capital Supply Chain: ($200,000 / $110,000) × 100 = 181.82%.

A return of 181.82% is solid, but let’s say you notice your inventory is much higher than it needs to be. By reducing excess stock, you could lower your working capital and boost that percentage even higher. That’s the kind of insight this metric can give you.

Tips to Improve Your Return on Working Capital Supply Chain

Now that you know how to calculate it, let’s talk about how you can make that number better. I’ve learned a few tricks over the years that have helped me streamline my own operations, and I’m happy to share them with you.

- Optimize Inventory: Too much inventory ties up cash. Use tools like inventory management software to track what’s selling and avoid overstocking. For example, I once cut my inventory by 20% by analyzing sales data, and it freed up cash without hurting sales.

- Negotiate Better Terms with Suppliers: If you can extend payment terms (say, from 30 to 60 days), you reduce your accounts payable, which lowers your working capital needs. I’ve found that building strong relationships with suppliers makes these negotiations easier.

- Streamline Logistics: Look for ways to cut shipping or warehousing costs. Maybe you can consolidate shipments or switch to a more cost-effective carrier. I saved 15% on shipping costs just by comparing rates from different providers.

- Improve Cash Flow: Encourage customers to pay invoices faster by offering small discounts for early payments. This boosts your cash reserves and reduces accounts receivable.

- Monitor Regularly: Don’t just calculate this metric once and forget it. I check mine quarterly to spot trends and catch issues early. You can set up a simple spreadsheet to track it over time.

Common Mistakes to Avoid

When I first started calculating this metric, I made a few blunders that threw off my numbers. Here’s what you should watch out for:

- Mixing Up Operating Income: Make sure you’re only including supply chain-related income and expenses. I once accidentally included marketing costs, and it skewed my results.

- Ignoring Seasonality: If your business has seasonal swings (like a toy store before the holidays), your working capital can fluctuate. Calculate this metric over a full year for a clearer picture.

- Overlooking Hidden Costs: Things like spoilage, theft, or unexpected shipping fees can sneak into your supply chain expenses. Double-check your numbers to ensure accuracy.

FAQs About Return on Working Capital Supply Chain

What’s a good return on working capital supply chain percentage?

It depends on your industry, but generally, a return above 100% is considered strong. Compare your number to industry benchmarks to see how you stack up.

How often should I calculate this metric?

I recommend checking it quarterly or at least annually. This helps you spot trends and make adjustments before small issues become big problems.

Can small businesses use this metric?

Absolutely! Whether you’re a one-person shop or a large corporation, this metric helps you understand how efficiently your supply chain is using your resources.

What’s the difference between return on working capital and return on investment (ROI)?

Return on working capital focuses specifically on the money tied up in your supply chain, while ROI looks at the overall profitability of an investment, like a new machine or marketing campaign.

Final Thoughts

Understanding how to calculate and improve your return on working capital supply chain can feel like unlocking a secret weapon for your business. It’s not just about crunching numbers—it’s about seeing where your money’s going and making sure it’s working as hard as you are. By following the steps I’ve outlined, you can get a clear picture of your supply chain’s efficiency and take action to make it even better. So grab your financials, plug in the numbers, and start optimizing.